Innova Solutions

Menu

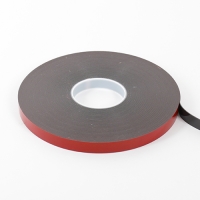

NovaBond XS110BFR

NovaBond XS110BFR is a self-extinguishing heavy duty acrylic pressure sensitive adhesive, impregnated with fire-resistant additives. NovaBond XS110BFR is a flame retardant, black foamed double sided acrylic adhesive tape with a red filmic liner. The product utilizes the latest in anti-combustible technology, consisting of an acrylic foam laminated with an acrylic adhesive, both of which are…

Adhesive Tapes, High Strength Bonding Tapes, Stronger Enquire NowDescription

NovaBond XS110BFR is a self-extinguishing heavy duty acrylic pressure sensitive adhesive, impregnated with fire-resistant additives.

NovaBond XS110BFR is a flame retardant, black foamed double sided acrylic adhesive tape with a red filmic liner. The product

utilizes the latest in anti-combustible technology, consisting of an acrylic foam laminated with an acrylic

adhesive, both of which are impregnated with the fire-resistant additives. When NovaBond XS110BFR comes

into contact with a flame, it will self-extinguish, without melting or dripping, and, when used as a bonding

medium, as intended, in a final finished construction it should not present an increased risk of flammability,

smoke generation or toxicity.

Applications

Any demanding bonding application of a wide variety of substrates where flammability, smoke generation or toxic gas production are critical to a product not being fit for purpose, such as: –

• Construction – Fixing Cladding, Wall & Elevator Panels

• Rail Sector and London Underground – Bonding signage, wall panels, trims, tactiles etc. in stations, tunnels and even rolling stock

• Marine & Offshore – Bonding signage, fixing Cladding, wall panels, ballistic protection etc.

• Aerospace and M.o.D. – Mounting of trims, panels & signage, trolley construction, equipment fascias etc.

• Vehicles – Mounting of internal trims, panels & badges.

• Electronics – Mounting components, facias, and component housings.

Formal and Indicitive Flammability, Smoke & Toxicity Testing

NovaBond XS110BFR has undergone formal testing for the following tests at Element Warringtonfire;

• ISO 4589-2: 1999*

(Generic Industry test, with a high relevance to the Rail Sector to test how much oxygen is required to sustain the material to combust)

*Further details available upon request

NovaBond XS110BFR performed exceptionally well during the Oxygen Index Test and achieved a R24 classification for hazard level 3 applications with an Oxygen Index of 39.3%. The tape was tested using as a stand-alone tape with fully exposed surfaces, to provide accurate results of its fire retardant properties. As a reference, the most stringent Rail specifications accept an Oxygen Index of 32% and The London Underground accept an Index of 34%

NovaBond XS110BFR has also completed indicative testing at Element Warringtonfire for the following European and British Standards;

• EN 13501-1: 2007 + A1: 2009*

(Construction Industry test to measure spread of flame, smoke generation and burning droplets)

• EN 45545-2: 2013 + A1: 2015*

(Rail Industry test to measure spread of flame, heat released and toxicity)

• BS 6853: 1999 Annex B.2 (Withdrawn)/S1085 Attachment A.2*

(Rail Industry / London Underground test to measure toxicity)

• UL94: 2013*

(US Underwriters Laboratory simple test for flammability and self-extinguishing properties)

All the above testing has been completed to provide end users with an indication of the tapes overall fire performance as a stand-alone tape in order to provide them with the peace of mind that the product has the credibility for use in terms of flammability, smoke generation and toxicity. This testing has been undertaken in good faith to demonstrate suitability for use in the customer’s final finished product construction and we believe that NovaBond XS110BFR, when used as a bonding medium to bond 2 or more substrates will not present any detrimental effect that will contribute to the final construction failing any fire testing in terms of flammability, smoke generation or toxicity. As with all Fire Retardant Testing, it is the users’ responsibility to test the tape within the complete and final product construction, in order to prove the suitability of the product within its intended use.

How to apply NovaBond XS110BFR

- Abrade (roughen) the surface to provide a ‘key’ to which the tape can bond, increasing the bond strength by as much as 35%

- Clean with NovaBond Surface Cleaner

- Prime the surface using NovaBond Surface Primer

- Independent tests at Loughborough University show that using the correct primer can increase final bond strength by up to 50%. Remove the blue silicon liner.

- Align the parts to be bonded.

- With firm pressure, apply NovaBond XS110BFR to one of the surfaces to be bonded.

- Using a NovaBond roller will allow the double sided acrylic tape to wet out and reach ultimate bond strength more quickly.

- Apply firm pressure to the bond with the NovaBond roller.

- Ultimate bond strength will be achieved in 72 hours.

Please contact us at enquiries@innovasolutions.co.uk for further information or to discuss your application.

Click HERE to link through to our full product range.

Innova Solutions: bonding people, fixing problems: +44 (0)1282 867 390