Innova Solutions

Menu

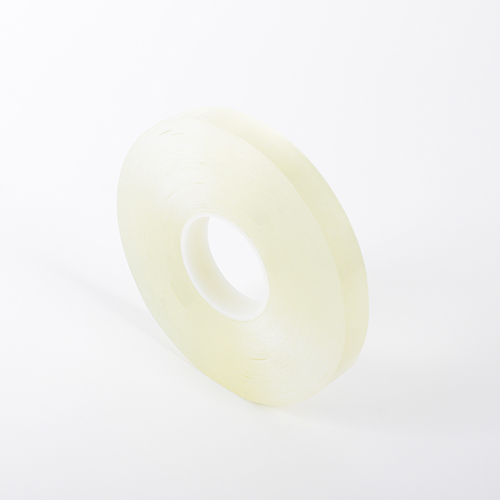

NovaBond SignFix LSE 80

Low surface energy tapes – NovaBond LSE 80 For the substrates conventional tapes struggle to bond, choose NovaBond LSE 80. NovaBond LSE 80 bonding tape – ideal for: Signage: Immediate bond strength on a wide variety of signmaking plastics (including, polypropylene, polyethylene and other thermoplastics) that traditionally resist adhesives. Manufacturing: Similarly effective on powder coatings.…

Adhesive Tapes, High Strength Bonding Tapes Enquire NowDescription

Low surface energy tapes – NovaBond LSE 80

For the substrates conventional tapes struggle to bond, choose NovaBond LSE 80.

NovaBond LSE 80 bonding tape – ideal for:

- Signage: Immediate bond strength on a wide variety of signmaking plastics (including, polypropylene, polyethylene and other thermoplastics) that traditionally resist adhesives.

- Manufacturing: Similarly effective on powder coatings.

Why NovaBond LSE 80 low surface energy tape?

Materials such as polypropylene and polyethylene are low surface energy plastics. When you apply adhesives and adhesive tapes to them the surface resists. Instead of letting the adhesive spread and grip (a process known as ‘wetting out’), the substrate acts like a well-waxed car bonnet, encouraging the bonding tape to simply slide away.

That’s why a low surface energy plastic needs acrylic tapes specifically designed for the purpose.

NovaBond LSE 80 delivers:

- Incredibly high tack – so it immediately grips the surface and forms a strong bond on low surface energy plastics

- Water clear for a near invisible bond

- Interior or exterior performance

How to apply NovaBond LSE 80 bonding tape

- Abrade (roughen) the surface to provide a ‘key’ to which the tape can bond, increasing the bond strength by as much as 35%

- Clean with NovaBond Surface Cleaner

- Prime the surface. Independent tests at Loughborough University show that using the correct primer can increase final bond strength by up to 50%. You can find the correct NovaBond Surface Primer here.

- Remove the clear filmic liner. Align the parts to be bonded.

- With firm pressure, apply NovaBond LSE 80 to one of the surfaces to be bonded. Using a NovaBond roller will allow the double sided acrylic tape to wet out and reach ultimate bond strength more quickly.

- Apply firm pressure to the bond with the NovaBond roller.

- Ultimate bond strength will be achieved in 72 hours.

NovaBond LSE 80 technical information

| Colour | Transparent |

|---|---|

| Thickness | 0.8mm |

| Standard roll dimensions temperature resistance according to ISTM D3654 method | 12 & 19 & 25mm widths x 33m rolls / -40⁰c centigrade to +120⁰c (short term: 150⁰c+) |

| Adhesion according to AFERA 5001 | Glass 37N / 25mm – Steel 39N / 25mm – PVC 30N / 25mm – PP 26N / 25mm – PE 15N / 25mm – PMMA 34N / 25mm |

| Cohesion according to AFERA 5012 | 20⁰ 30N / 625mm² – 70⁰ 10N / 625mm² |

| Application | Minimum 15⁰c (ideally between 21⁰c and 40⁰c) |

| Temperature | Relative humidity 55% ± 10% |

| Liner | Clear film |